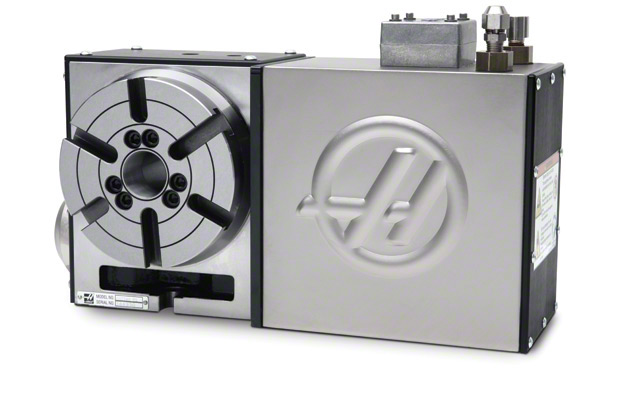

Haas Vector Drive Repair

HAAS Vector Drive Repair As An Excellent Alternative To Complete Equipment Replacement

Worldwide Industrial Solutions is the only repair company that can repair your equipment back to factory specs. We have stocked OEM parts, trained technicians and the capabilities to fully load test all of the HAAS vector drives, servo motors, amplifier cards, I/O boards, 320 volt power supply, CRT and more.

Quality repairs are an excellent alternative to complete equipment replacement, saving you financial resources and time. Worldwide Industrial Solutions technicians will perform a complete diagnosis of the equipment to gather information about the problem with the HAAS vector drive. Common problems, for instance, include overheating, unstable performance or complete failure.

Component-based HAAS Vector Drive Repair

Component-based vector repair will also save your company resources. This is why we always carefully inspect all individual elements of a vector drive: cables, wires, capacitors and resistors.

We can also troubleshoot vector drive HAAS software problems and updates. And after all HAAS repairs have been carried out, our specialists will perform the necessary thorough testing of the vector drive in a controlled environment.

Common problems

1. Overcurrent Fault

Overcurrent faults can occur if the current drawn by the spindle motor exceeds the specified limit. This may result from issues such as a short circuit in the motor windings, a faulty IGBT (Insulated Gate Bipolar Transistor), or problems with the power supply.

2. Overvoltage Fault

Overvoltage faults happen when the voltage in the drive system exceeds the allowable limit. This can be caused by issues with the power supply, regenerative energy from the motor, or faults in the drive circuitry.

3. Overheating

If the Vector Drive becomes too hot, it may trigger an overtemperature fault. This can occur due to inadequate cooling, fan failures, or high ambient temperatures. Proper ventilation and cooling are crucial to prevent overtemperature issues.

4. Encoder Feedback Issue

The Vector Drive relies on feedback from the encoder to control the spindle motor speed accurately. Encoder faults, such as misalignment, signal loss, or damage, can lead to issues like speed fluctuations, loss of position control, or even motor stalling.

5. Communication Errors

If there are communication errors between the CNC control unit and the Vector Drive, it can lead to issues in transmitting speed commands or receiving feedback. This can result in inconsistent spindle speeds or a loss of control.

6. Control Board Failures

Faults in the control board or electronic components can result in erratic behavior or complete failure of the Vector Drive. This may include issues with the microprocessor, I/O circuitry, or other control components.

7. Software or Firmware Issues

Like any electronic device, issues with the software or firmware can lead to operational problems. Regular updates and checks for compatibility between the CNC control software and Vector Drive firmware are essential.

FAQ

Q: How can I identify if my Haas Vector Drive is malfunctioning?

A: Look for symptoms such as erratic spindle behavior, unexpected stops, error messages on the control panel, or unusual sounds. If you suspect an issue, it’s advisable to consult with a professional for diagnostics.

Q: What is the typical turnaround time for Haas Vector Drive repairs?

A: Turnaround time can vary depending on the specific issue and workload. We strive to provide efficient service, and our team will communicate the estimated repair time upon assessment.

Q: Can you repair drives from older Haas machines?

A: Yes, we specialize in repairing drives from a range of Haas CNC machines, including older models. Our technicians are familiar with various generations of Haas Vector Drives.

Q: How often should I have my Haas Vector Drive inspected for preventive maintenance?

A: Regular preventive maintenance is essential for prolonging the lifespan of your drive. Depending on usage and operating conditions, an annual inspection is recommended. This can help identify potential issues before they become major problems.