Electronic Repair

Worldwide Electronic Repair Is A Guarantee Of Reliable Manufacturing Operations

Nowadays in a competitive market environment with high standards all global industrial companies have to maximize performance of their facilities in order to keep up with customer demand and needs. This is why IC chips, power regulators, fuses and capacitors are also overloaded and eventually fail. This is most likely why you are on this page and we are here to offer you a professional general electric solution.

Worldwide electronic repair is the key to ensuring reliable operation of all manufacturing lines. Properly functioning global electronics help to significantly reduce operating costs and saves the company’s money on repairs of the main industrial equipment.

Common Symptoms of Board Faults

1. Power Supply

- Symptoms: Unstable machine behavior, random resets, or complete power loss.

- Causes: Issues with the power supply board, such as faulty capacitors or power distribution components.

2. Communication Errors

- Symptoms: Loss of communication between different electronic boards, error messages on the control panel, or erratic machine behavior.

- Causes: Faulty communication circuits, damaged cables, or issues with connectors.

3. Firmware or Software Glitches

- Symptoms: Unexpected program interruptions, control panel errors, or failure to execute commands.

- Causes: Bugs or glitches in the firmware or software running on the electronic boards.

4. Encoder Feedback Issue

- Symptoms: Positioning inaccuracies, inconsistent spindle speeds, or errors in tool positioning.

- Causes: Problems with the encoder feedback circuits, misalignment, or damage to the encoder itself.

5. Faulty Input/Output (I/O) Boards

- Symptoms: Inability to read or respond to inputs, malfunctions in machine control, or errors in sensor feedback.

- Causes: Defective input/output boards, damaged connectors, or issues with signal processing.

Look Through Every Step Of The Worldwide Electronic Common Symptoms With Worldwide Industrial Solutions

Global electronics solutions and industrial electronic equipment repair include troubleshooting, maintenance and repair of electronic devices and equipment systems used in industrial operations.

When contacting our company for global electronics solution, you can be guaranteed that you will receive top-notch service from Worldwide Industrial Solutions experts and every part will go through every step of the worldwide electronic repair process that includes:

- Testing and diagnostics

- Troubleshooting

- Repair or replacement of components

- Modernization

- Verification, calibration and testing

- Planned maintenance of industrial electronic equipment

- Documentation and warranty

Contact Us For Professional Global Electronics Solution

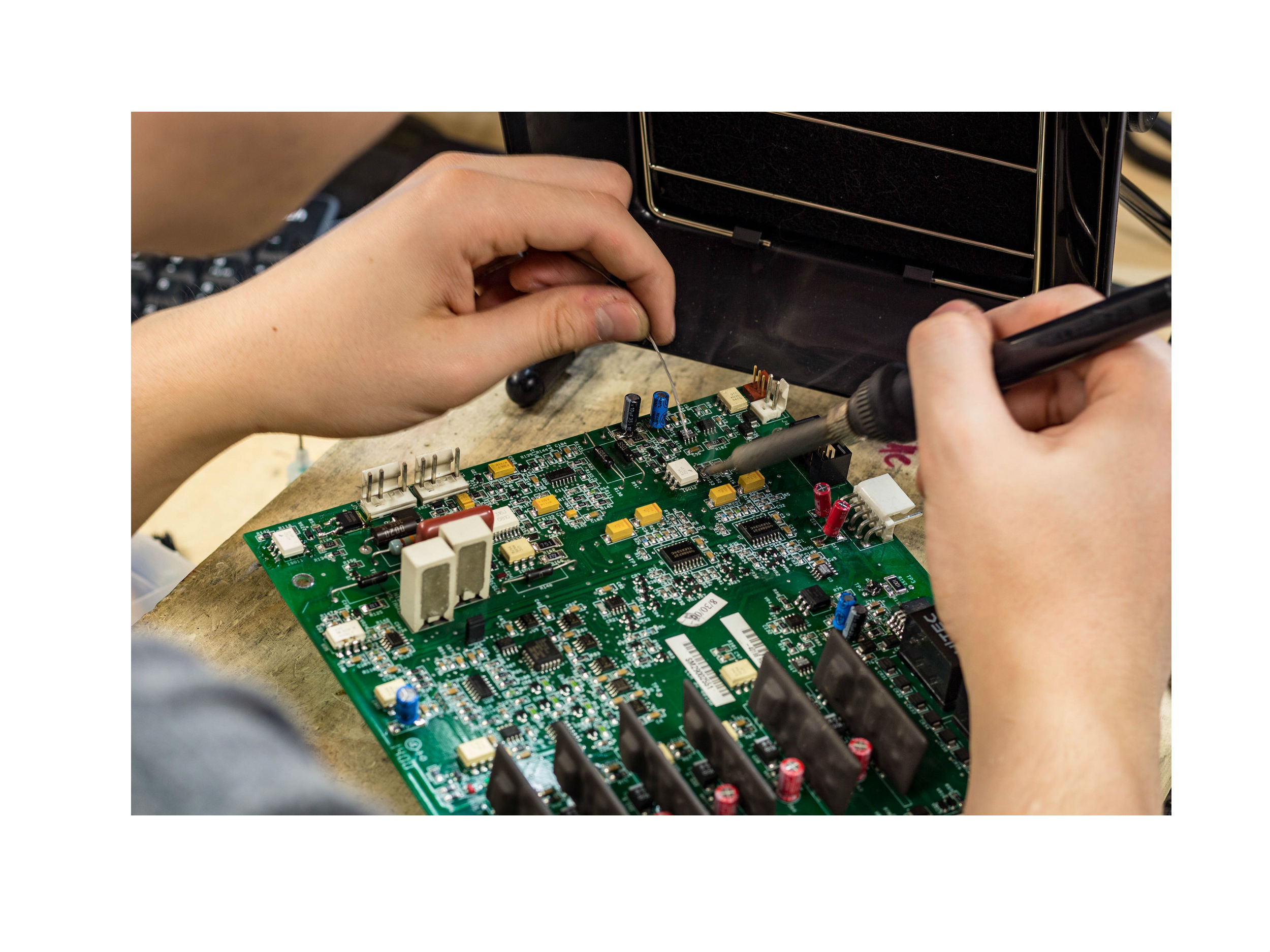

Each intricate component on this circuit board undergoes rigorous individual testing before the unit is meticulously packaged for return to the customer. From processors and main boards to Coldfire and Mocon boards, our testing spans resistors, diodes, transistors, MOSFETs, crystals, IC chips, power regulators, transformers, fuses, and capacitors. Specializing in global electronics, we extend our expertise to repair servo motors, AC/DC drives, displays, hydraulics, and printed circuit boards. Beyond standard worldwide electronic repair, we excel in locating rare components that may elude other repair companies. Moreover, if your equipment requires a program chip replacement, we possess the capability to duplicate and reload the program onto the new IC chip.

FAQ

Q: What are common signs that electronic boards may be malfunctioning?

A: Look out for erratic machine behavior, unexpected resets, error messages on the control panel, or issues with communication between different machine components. Unexplained interruptions in program execution or inconsistent sensor feedback may also indicate electronic board problems.

Q: How can I identify a power supply issue with the electronic boards?

A: Power-related problems may manifest as unstable machine behavior or complete power loss. If you experience random resets or notice unusual behavior during machine operation, it’s advisable to check for issues with the power supply board. This could include inspecting capacitors and power distribution components for faults.

Q: How can I protect electronic boards from power surge damage?

A: Employing surge protection devices and ensuring a stable power supply can help protect electronic components from power surges. Installing an uninterruptible power supply (UPS) is also recommended to prevent abrupt shutdowns during power fluctuations.

Q: What preventive measures can I take to avoid electronic board issues in my CNC machine?

A: Visual inspections for signs of wear or corrosion, proper cooling system maintenance, and careful handling of electronic components, can help minimize electronic board issues. Following manufacturer guidelines for machine operation and maintenance is crucial.